Fluids Solutions

Fluids Solutions from NES-WES

Northeast-Western Energy Systems USA, LLC has strategically partnered with Q8Oils to be an exclusive distributor to offer complete comprehensive fluids packages which include lube oil, gear box oil and coolant. Our goal is to provide the longest lasting oil life at the most cost-effective price that will significantly lower your overall lubricating oil costs. Q8Oils Mahler is a range of high-quality lubricants for engines using all types of gas, including natural gas, biogas, landfill gas, sewage and other highly polluted gases. These oils offer outstanding benefits such as high oxidation and nitration resistance for long service life, low ash deposit tendency and good resistance against pre-ignition, excellent anti wear properties to protect the engine against valve seat recession and high acid neutralizing capacities as a result of high Total Base Number (“TBN”) retention.

Gas engines are subjected to extreme operating conditions, especially around the combustion chamber. This results in significant technical challenges for lubricant manufacturers, particularly in terms of oxidation- and deposit control with outstanding TBN retention. Operating conditions vary substantially and Q8Oils can provide advice on the best oil for your application. NES-WES will perform comprehensive expert analysis and management of lube oil, coolant and fuel gas sampling to ensure adherence to OEM requirements.

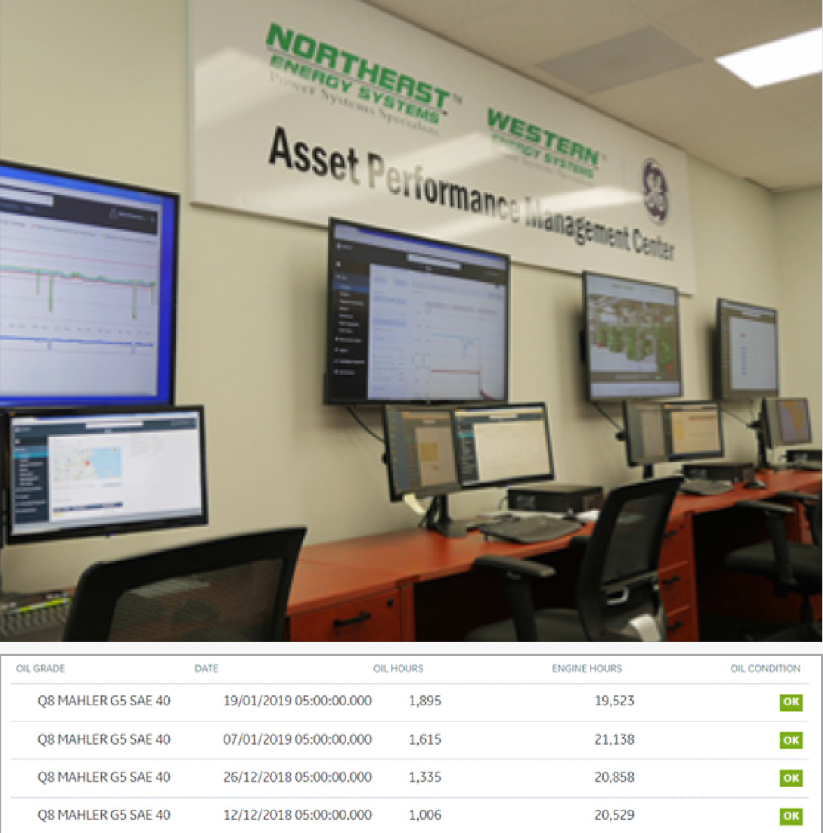

The NES-WES Asset Performance Management Center allows you to monitor your oil life cycle through the MyPlant application. - https://myplant.neesys.com/myplant

NES-WES FLUIDS SOLUTIONS LIFE CYCLE

fluids sample:

- Lubricating oil, gearbox oil, and coolant.

- In Stock.

- For a quote, please reach com to neesysparts@neesys.com or weesysparts@weesys.com.

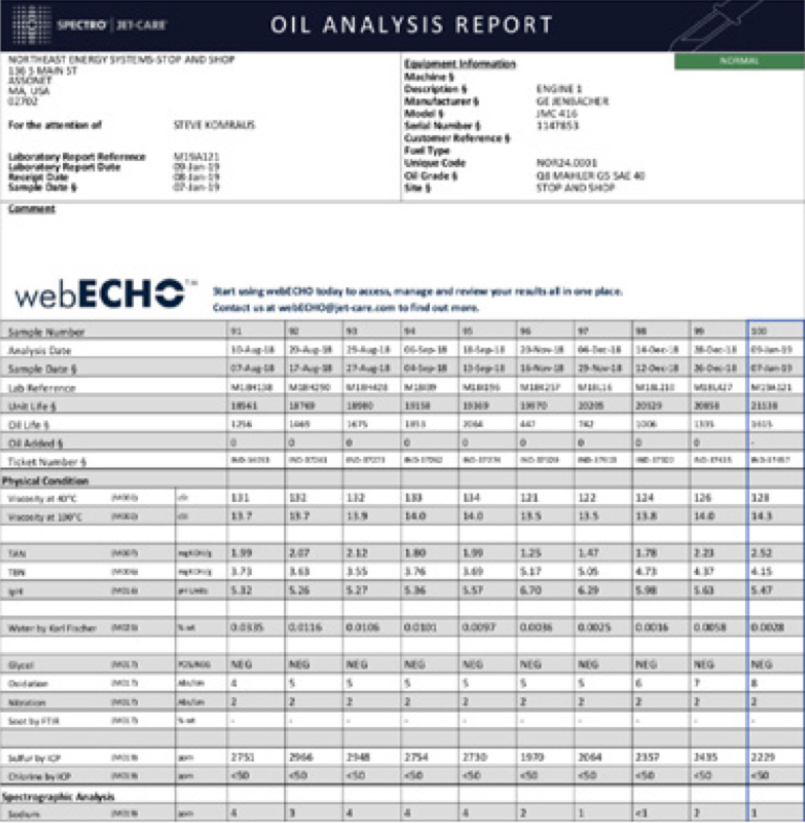

JETCARE LAB ANALYSIS:

- Fast, Accurate Analysis: results sent within two working days of receipt of your fluids sample.

- 24/7/365 Availability - prioritized reporting within a few hours.

- Technical Expertise- Our experienced team of engineers and analysts provide an unrivaled technical service.

PUBLISHED RESULTS:

Oil Management:- Sample date, analysis date, sample number, oil life, oil added.

- Viscosity, TBN, TAN, IpH, Oxidation, Wear Metals, etc.

APMC AND MyPlant REVIEW:

- Technical expertise.

- Predictive Analytics.

- Fluids Report storage.

FLUIDS SUPPLY AND DELIVERY:

Warehouse:- Bristol, PA.

- Edison, NJ.

- Woburn, MA.

- Brea, CA.

- Anchorage, AK.

- Pail, Drum, Tote, and Bulk.

- Common carrier and tanker.

- Tote/Drum Removal.

- Used oil tank removal.

WHY OIL MANAGEMENT?

Quality oil leads to:

Lowering total operational costs (and TCO).

- Less oil filters, o-rings.

- Less man hours.

Cleaner engines.

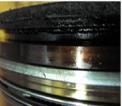

- Traditional and modern type 'low TBN' products can give hard abrasive deposits (leading to ring sticking, etc..).

Longer oil drain.

poor quality oil

- Hard abrassive deposits.

- Thermal / oxidative stress on oil very high.

- Issues: Ring sticking.

- Liner Laquering.

HIGH quality oil

- Clean pistons.

- Clean liners (low oil consumption).

- Good dispersancy / solubility (long filter life).

PRODUCTS

Oil Sample Analysis

| Sodium | (M019) | ppm | 2 |

| Boron | (M019) | ppm | <1 |

| Silicon | (M019) | ppm | 4 |

| Iron | (M019) | ppm | 3 |

| Aluminum | (M019) | ppm | 1 |

| Chromium | (M019) | ppm | <1 |

| Molybdenum | (M019) | ppm | <1 |

| Copper | (M019) | ppm | 3 |

| Lead | (M019) | ppm | <1 |

| Tin | (M019) | ppm | <1 |

| Nickel | (M019) | ppm | <1 |

| Titanium | (M019) | ppm | <1 |

| Silver | (M019) | ppm | <1 |

| Manganese | (M019) | ppm | <1 |

| Potassium | (M019) | ppm | <1 |

| Phosphorus | (M019) | % wt | 0.0358 |

| Calcium | (M019) | % wt | 0.1439 |

| Zinc | (M019) | % wt | 0.0417 |

| Barium | (M019) | % wt | <0.0001 |

| Magnesium | (M019) | % wt | 0.0003 |

Sodium: Antifreeze inhibitors, additive in some gasoline engine oils.

Boron: Detergent/dispersant additive, antifreeze inhibitors.

Silicon: Airborne dirt (as silicium dioxide ; quartz (*) ), sealers, gaskets, antifreeze inhibitors, In Landfill -and Biogas gas as Silixane ( silicon & oxygen & alkaline) (**))

Iron: Cylinders, rotating shafts, the valve train, and any steel part sharing the oil.

Aluminum: Pistons, bearings, cases (heads & blocks).

Chromium: Rings, a trace element in steel.

Molybdenum: Anti-wear additive, coating on some new rings (washes off as break-in occurs).

Copper: Brass or bronze parts, copper bushings, bearings, oil coolers.

Lead: Bearings.

Tin: Bearings, bronze parts, piston coatings.

Nickel: Trace element in steel.

Titanium: Trace element.

Silver: Trace element.

Manganese:Manganese: Trace element

Potassium: Antifreeze inhibitor, additive in some oil types. (Kalium)

Phosphorus: Anti-wear additive.

Calcium: Detergent/dispersant additive.

Zinc: Anti-wear additive.

Barium: Detergent/dispersant additive.

Magnesium: Detergent/dispersant additive.

physical condition of the oil

| Physical Condition | |||

| Viscosity at 40℃ | (M002) | cSt | 121 |

| Viscosity at 100℃ | (M002) | cSt | 13.5 |

| TAN | (M007) | mgKOH/g | 1.25 |

| TBN | (M006) | mgKOH/g | 5.17 |

| lph | (M016) | pH Units | 6.70 |

| Water by Karl Fischer | (M023) | %wt | 0.0036 |

| Glycol | (M017) | POS/NEG | NEG |

| Oxidation | (MO17) | Abs/cm | 5 |

IpH

(Initial pH, measured at start of TAN test) IpH is a measure of the overall acidity of an used oil mixture. Pure water is said to be neutral (pH ~7.0). Solutions with a pH less than 7 are called acidic and solutions with a pH greater than 7 are called basic or alkaline.

Oxidation

Oxidation occurs as lubricant molecules are exposed to oxygen over long time periods. This process is accelerated by high operating temperatures.

Oxidation is perhaps the most predominant problem for natural gas engines.

Oxidation is often accompanied by:

- viscosity increase

- oil filter plugging

- varnish, sludge and sediment formation

- additive depletion

- base oil breakdown

- loss of lubricity

- acid number (TAN) increase

- loss in foam control

- rust formation and corrosion

To avoid these problems it is binding to change the oil asap when the maximum value is reached.

Limit value is: maximum 20 Abs/cm*

Analytics and Trending